Advanced Techniques In Model Making For Intricate Craft Molds

Precision Model Making: The Foundation of High-Quality Molds

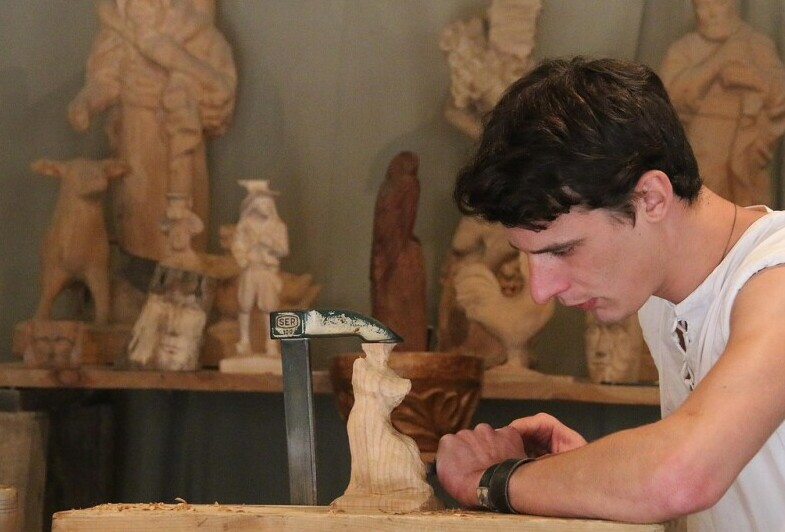

Using advanced techniques in model making is what separates ordinary molds from extraordinary craftsmanship. Every detail in a model matters, from the sharpest edge to the tiniest groove. A well-crafted master model captures details exactly as envisioned, leading to superior final products.

To achieve this level of accuracy, selecting the right tools is crucial. Fine-tipped carving tools provide excellent control for intricate manual detailing. CNC routers introduce an added layer of precision, particularly for complex patterns that demand exact replication.

Alongside these tools, certain advanced techniques help elevate your model-making game. For textures, focus on building layers gradually, allowing for depth and complexity. Sharp edges are crucial for clear definition, so maintaining your tools and following a methodical approach helps immensely.

One of the most enlightening parts of mastering this craft is hearing from those who’ve perfected the craft through experience. look for and consider a project where precision has been the key to their success. Maybe it was delicate jewelry mold that demanded perfect replication of every detail or an architectural model where each element had to fit perfectly without error.

Learning from such projects can provide valuable insights, helping you understand where to focus your efforts and how to overcome common challenges. With precision and detail at the core of your model-making process, the quality of your final product will reflect the care and skill you have invested. The beauty of video channels only helps this process and that’s what that is on top of my to-do list.

Table of contents

Choosing the Right Materials for Advanced Techniques in Model Making

The foundation of any high-quality mold is its master model, and selecting the right material significantly impacts durability, surface finish, and mold lifespan.

Material Breakdown:

- Clay: Highly flexible and ideal for intricate sculpting. However, its softness can be a drawback for sharp, permanent details.

- Resin: Offers durability and a smooth finish, making it excellent for polished models.

- Wood: Provides stability, particularly for large models, though its grain can affect detail transfer. Finishing with resin or paint helps overcome this limitation.

- 3D-Printed Materials: Revolutionizing model making with unmatched precision and repeatability, though costs and learning curves vary by software and printer quality.

Understanding how different materials influence your model is vital. It impacts wear and tear, the final mold’s life span, and the kind of textures you’ll be able to achieve. Talking to experienced model makers can offer further perspective, helping you make informed choices based on the project at hand. So consider joining groups or forums.

Advanced Sculpting & Finishing Techniques

Mastering advanced sculpting and finishing methods enhances model accuracy and overall mold quality.

Sculpting Techniques:

- Hand-Sculpting: Allows for an organic touch and refined details, relying on craftsmanship and practice.

- CNC Routering: Offers high-precision carving, maintaining consistency across multiple pieces.

- Digital Carving: Increasingly popular, this technique merges traditional sculpting with technological advancements.

Advanced Techniques in Model Making & Finishing Techniques:

- Sanding & Smoothing: Eliminates imperfections for flawless mold replication.

- Precision Spray Coating: Ensures even surface texture and enhances the quality of silicone or resin molds.

Each step contributes to the overall effect of your final product, making it essential to use the best tools and techniques available. A final coat of a suitable spray paint is one of the easiest ways to achieve the level of surface finishes you want. Remember, silicone will copy that surface exactly!

Multi-Part Molds & Complex Geometries

Crafting a model with intricate shapes sometimes requires a different approach. Multi-part molds are the secret to capturing those tricky undercuts and complex geometries that a single-piece mold just can’t manage.

The decision to use multi-piece molds often comes down to the need to preserve the finished cast piece of your design when demolding, without damaging the piece or mold. When a shape includes deep recesses or overhangs, dividing it into sections can make it much more manageable. Breaking down a complex design into simpler components makes the release process much simpler. And it reduces the risk of damaging your model after all the hard work you put in.

Designing interlocking sections is the best strategy. Precision in aligning these parts is key. If sections don’t fit together seamlessly, it will lead to misalignment issues and detail loss. And a finished piece that can’t be sold. Careful planning in the initial stages can save a lot of trouble down the line when final production begins.

It’s important to incorporate features like registration keys or locating lugs, which help sections fit together snugly, ensuring the mold captures every detail correctly and consistently. By doing so, you maintain the precision and quality of your molds and the final piece every time.

Reinforcing & Strengthening Molds for Longevity

Once you have put a lot of time, energy and skill into making your model, creating durable mold(s) is critical if you’re looking to get the most out of your efforts. It’s not just about making a mold; it’s about making sure it lasts for at least its intended production run. Reinforcing techniques are the best and easiest way to extending the molds life and usability.

Reinforcement Strategies:

- Fiber Reinforcement: Fiberglass, polypropylene, or carbon fibers strengthen mold shells.

- Backings & Supports: Wooden or metal frameworks provide stability, especially for large or awkwardly shaped molds.

- Regular Maintenance: Inspect molds for cracks and wear, making repairs as needed to prevent degradation.

Using these reinforcement methods ensures long-term mold reliability, saving time and resources in repeated production runs.

As an Amazon Associate, I earn from qualifying purchases.

This post contains affiliate links. If you buy through them, I may earn a commission at no extra cost to you.

Digital Tools & 3D Printing in Advanced Techniques in Model Making

3D printing is most certainly a game-changer in the world of model making, opening up new possibilities for creating complex and highly detailed molds. I intend to be moving into this realm in the 2nd quarter of 2025, and making videos in detail, but it will be a budget-available choice when the time comes around—Creality if it’s tight or Prusa if I have a little more available. Its ability to produce precise and repeatable master models is remarkable, making it a valuable tool for modern craftsmen.

Incorporating digital tools into your production puts you ahead of many as it combines traditional crafting techniques with cutting-edge technology. 3D modeling software enables you to design intricate model masters with high accuracy and save them digitally, translating your complex ideas directly into tangible models. This fusion of technology and art can significantly enhance the quality and precision of your models.

Keeping an eye on future trends in 3D printing technology can provide a competitive edge. As printers evolve, allowing for faster, more detailed printing with advanced materials, staying updated can help you remain at the forefront of model-making innovations. May be learning important job skills along the way. Check out this post on 3D printing, click here

Conclusion: Elevate Your Advanced Techniques in Model Making Skills

By incorporating precision tools, selecting the right materials, mastering sculpting techniques, and embracing digital advancements, model makers can achieve professional-quality results. Whether refining traditional methods or integrating 3D printing, attention to detail remains the key to crafting superior molds.

Next Steps: Continue refining techniques, engage with expert communities, and stay informed about emerging technologies to push the boundaries of model-making excellence.

Contact Us

We hope you found this information on advanced techniques in model making helpful! If you have any questions or need assistance, feel free to reach out. Please note that due to government regulations, you’ll need to sign in and confirm your message. We apologize for any inconvenience.

Author: Rob

“Precision truly sets apart an exceptional model from an ordinary one. The detailed breakdown of tools, techniques, and materials in this post highlights the importance of every step in the process. Mastering both traditional craftsmanship and modern advancements like 3D printing is key to achieving outstanding results. Thanks for emphasizing the value of precision and continuous learning in model making!”

Hi Herman,

And thank you for your comments, 3D printing has to be the way forward, but for great quality finish you need to have a great quality of printer to have a good surface finish.

Thank you, Rob

Hello Rob!

This was such an informative read!

Precision in model-making can be so challenging, especially when working with intricate details. Do you have any tips for maintaining consistency when casting multiple pieces from the same mold? I’ve found that small variations in mixing or curing time can sometimes affect the final result. What’s your favorite material for capturing fine details in molds—do you prefer silicone, or have you had success with other options?

Looking forward to your answers!

Angela M 🙂

Hi Angela,

Glad you liked the read! Consistency is always the key to successful pours. Keeping your silicone molds clean and covered, and conditioning them now and then will extend their lives.

Rob