An Article On Cast Stone Supplier

Table of contents

- “From Garage-Made Pieces to Phenomenal Growth:

- My Cast Stone Adventure”

- The Beginning of A Cast Stone Supplier

- Lift Off. & Cast Stone

- The Basic Materials Needed For Production.

- Cast Stone Supplier And The Basic Requirements.

- The First Mechanical Mixer As a Cast Stone Supplier.

- How Hard Work & Grit Turned Into a Cast Stone Supplier.

- Cast Stone Supplier & The Selection of Raw Materials

- White Cement Near Me.

- Cast Stone Suppliers Nightmare Impurities in White Cement.

- How A Cast Stone Supplier Colors The Mixes.

- Other Additives.

- A Cast Stone Supplier & The Reinforcing.

- Wet Cast Limestone.

- Cast Stone Supplier And Biodegradable Release Agents.

- Texturing With Baking Soda.

- Assessing The Raw Products For A Cast Stone Supplier.

- Building A Connection with Your Suppliers.

- Basic List Of Raw Materials For A Cast Stone Supplier.

- Moving Forward.

- Contact Us

“From Garage-Made Pieces to Phenomenal Growth:

My Cast Stone Adventure”

An article on cast stone supplier is because in the early 1990s, in the sunny state of Florida, I found myself at a crossroads. For years, I had been exclusively installing wet cast stone—a craft that demanded precision and dedication. Before that, I had been a builder with many trades at my fingertips. These included bricklaying, tiling, marble work, and plastering and always involved in general construction, in one country or another. But now fate had other plans for me.

The Beginning of A Cast Stone Supplier

One day, a customer approached me in a bind. Their manufacturer, couldn’t supply the cast stone pieces they needed for nearly two months. This was one of the same companies I was currently working with. The pressure was on, and I had a decision to make: Could I step up and create those pieces myself?

With confidence, I accepted the challenge. In the humble confines of my garage, armed with determination, my fiancee and a mixing drill, I set to work. Piece by piece, I crafted the cast stone pieces that would save the day. When the customer and their influential client saw the results, they were ecstatic. Little did I know that this seemingly small act would set the stage for something much greater.

I/We promote transparency. This post or site may contain affiliate links. Which means only if you make a purchase through these links, not just by clicking, I/we may earn a small commission at no extra cost to you.

As an Amazon Associate, I earn from qualifying purchases

Lift Off. & Cast Stone

From that pivotal moment, my journey took off. Phenomenal growth followed, year after year over the next six to seven years. I moved and expanded my operations four times, eventually occupying over 100,000 square feet of space at its peak. Our turnover reached an impressive £20,000,000 within my group of companies.

The Basic Materials Needed For Production.

If you’re venturing into the world of cast stone. You’re engaging with a tradition that blends art and engineering to create elements that enhance buildings and landscapes. Before you immerse yourself in this craft, or go forward to build or remodel a project using cast stone. It’s crucial to understand what cast stone is and why the right suppliers are integral to your success. Whether you are setting up a full-scale operation or working on a small project at home in your garage or shed. Many of the same principles and needs apply. And if you just intend to buy the product then it’s better that you are fully informed.

Cast Stone Supplier And The Basic Requirements.

But let’s rewind to the basics—the raw materials that fuelled this remarkable ascent. I started with just a few of my trusty tools. A mixing drill, a paddle, and a mixture of small tools, some powered, many not. And a keen eye for quality. White cement we purchased from Home Depot, and by the 112-pound bag, one at a time. It became our lifeblood. We guarded it like gold dust, because the white cement price was a huge factor in our daily budget. But knowing that each bag held the potential for progress & profit. I had nightmares over the white cement price. If I remember it was $22 back then.

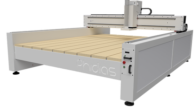

The First Mechanical Mixer As a Cast Stone Supplier.

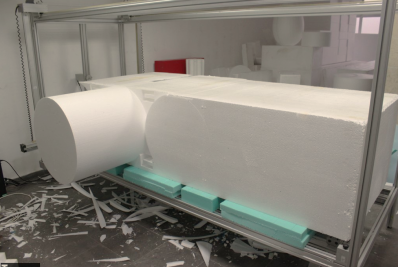

When I hired my first employee, we celebrated a new milestone. Together, we invested in a modest Home Depot electric mixer. His joy was contagious, and our production soared. I continued to design and make the molds and complete the installations, while he meticulously crafted the pieces. We even took on deliveries, building a seamless partnership.

Today, as I reflect on those early days—the garage, the determination, and the camaraderie. I’m reminded that success often begins with a single step. From those garage-made pieces to the vast enterprise we became, it all started with a willingness to say, “Yes, I can handle that.” and a dream.

How Hard Work & Grit Turned Into a Cast Stone Supplier.

And so, remember this: Hard work, determination, and a touch of resourcefulness can transform the ordinary into the extraordinary. Your journey, like mine, is filled with untapped potential waiting to be realized. Now you can understand how I know so much about this industry. Admittedly my lifelong involvement with construction did help, particularly my bricklaying, carpentry, tiling and plastering abilities.

Cast Stone is a refined architectural concrete building unit manufactured to simulate natural-cut stone. It can be used in unit masonry applications. Or be applied as a surface treatment, which is more common in the USA. It’s found in an array of structures, from grand historical renovations to intricate garden ornaments. The making of cast stone is precise; it demands a mix of high-quality raw materials, skill, and technology.

A key pillar of cast stone manufacturing is knowing and sourcing your materials and tools. Whether you’re fashioning facades that echo time-honoured aesthetics or adding flair to a new design. Having reliable suppliers ensures that your cast stone mixture is spot-on. And your tools are up to the task, and your final products are impeccable.

Cast Stone Supplier & The Selection of Raw Materials

Crafting cast stone requires a lot of quality ingredients to ensure the final product boasts both beauty and durability. I’m going to point out what matters. How to pinpoint the right suppliers for the essential raw materials that make up any premium cast stone mix. This isn’t just about finding the lowest price. It’s also about ensuring the materials you choose are up to par for creating your premium Cast Stone products.

First up, you’re going to need to zero in on suppliers. Finding cast stone suppliers near me was the backbone of my cast stone operation: sand and aggregates. So I would look for a sand/gravel quarry near me. The purity, grain size, and colour, of the aggregates matters. The latter varies depending on where you are located. And it can contribute to the texture, color and strength of the stone. Not all sand is equal, so choose something that works with your needs and your quality standards. And that is readily available with an on-time delivery service.

White Cement Near Me.

White cement near me is very important. Not just available at Home Depot and their high prices, it is very important for logistics. And for costings as it is the highest-priced ingredient. Sand & aggregates from stone quarries, you can always create a an in expensive workaround for. But good cement is critical, and not so easy to find. And the bulk of the products we made evolved around white cement. We did have several projects over the years that used grey cement.

Cast Stone Suppliers Nightmare Impurities in White Cement.

Now when I say white cement did you know there is a pure white, and there are others with various impurities in them? There are not many white cement manufacturers and distributors. So when I uncovered that information and then found I was having trouble maintaining colour on one quite large contract.

I dug deeper and analysed the mixing crew and process. I found the cause, fine pieces of a blue particle in the white cement mix. It turned out this cement was From Holland and I was in Florida. So from then on I was very particular about where I bought my cement. The other most important factor about cement is the Mls, this is a reference to the fineness of the cement. The finer the better the mix and colour disbursement. The best white cement suppliers I ever used came from Colombia. Go figure, right?

How A Cast Stone Supplier Colors The Mixes.

Next, the pigments. They give cast stone its varied and vibrant or subtle hues. You’re going to want pigments that come from a reputable manufacturer that operates a consistent manufacturing process. Many colorings I have used are made and mixed from different oxide powders. So the manufacturers have their secret formula which they give a name to. Then we as cast stone manufacturers would concoct our secret formulas. This made it very difficult for the competition to replicate our mixes. In the long term value & availability of the provided pigments are the important points.

Other Additives.

Additives can play a role in the mix as well. They can enhance the stone’s properties, like reducing the water content without compromising the workability or accelerating curing and demolding times. This means scouting for suppliers who have a range of additives and can advise on their use. Each additive you select should serve a purpose in your stone if you are going to use anything other than the basic. Just like too much of the pigments can weaken your mix or cause you to use more cement. There are a few other additives that if not used correctly can do the same.

A Cast Stone Supplier & The Reinforcing.

Concrete reinforcing fibres, non-ferrous. Over the years I started out using different products that caused me inherent problems. Particularly with any ferrous products. As the business grew and I evolved, I eventually only used non-ferrous reinforcing. Yes more expensive, but far fewer issues with hairline cracks or corrosion just a few years later. Finding the right fibre is really important. It can depend on your mixing methods and the quality of the labour that is batching the mixes. Many fibres can “clump”in the mix, others show through on your finished pieces. And if you are not careful you can end up with what I called “hairy stone”.

Fibreglass twisted rebar was a game changer for me. The smaller diameter rods, which came in 20′ (6m) lengths were perfect for making columns. Especially when we incorporated some of the fibers in the mix too.

Wet Cast Limestone.

If we were making our wet-cast version of limestone, only a few of the methods in the product manufacturing process were different. The quality of the molds, the type of raw aggregate we used. And the exacting processes needed to complete the finish after the piece was demolded. We used an aggregate with a lot of fine silica content that would shine through after the final processes. This was normally sourced from a different supplier.

I will cover our approach and processes to this wet-cast limestone product in a later post.

Cast Stone Supplier And Biodegradable Release Agents.

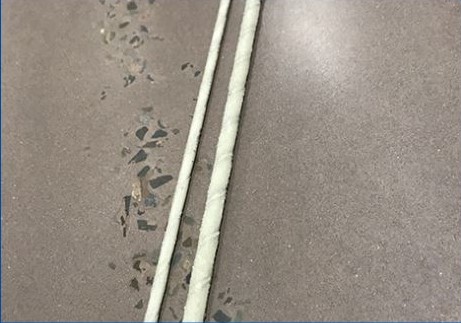

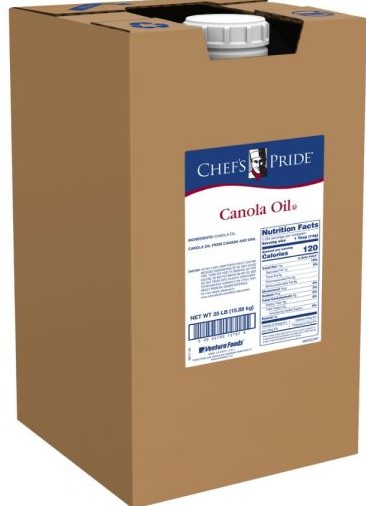

Release agents can vary for different finished products and what the mold is made from. A textured finish will be fine with a mixture of solid cooking fats and cooking oil, both are biodegradable. And for smooth products in most molds, a light coat of cooking oil works well. But for smooth products being produced in RTV rubber molds, these require special releases. And Platsil silicone molds only need the occasional spray of silicone, More for conditioning and storage.

Texturing With Baking Soda.

The most common texturing product I have used is baking soda. What a multi-use product that is, we use it in the home, and commercial cooking. And I used it by the pallet load for my wet-cast textured stone. To use it this way it’s necessary to mix a reasonable quantity in a bucket with a little water. Not too much, enough to make it “lumpy”. Then let it dry just a little, and now it will have different-sized lumps. After a little practice, you can form the perfect texture as the baking soda sticks to the release grease/oils

Assessing The Raw Products For A Cast Stone Supplier.

Assessing the quality and consistency of each raw material is paramount. A supplier might offer you a great deal, but if their sand has impurities, that deal becomes a liability. Always ask for samples and test the materials in your own mixes.

Building A Connection with Your Suppliers.

Building a relationship with suppliers goes beyond the initial purchase. You might find that establishing long-term partnerships with suppliers who offer reliability, transparency, and good communication can greatly benefit your operations. They can work with you on pricing, understand your needs, and ensure a consistent supply.

Remember, your first attempt doesn’t need to be your last. You can always adjust your approach down the road as you discover suppliers that better meet your needs or if your business model evolves.

Basic List Of Raw Materials For A Cast Stone Supplier.

- 1, Coarse Sand, or Silica sand

- 2, Small-Sized Aggregate. A 3/8″ to fine silica aggregate.

- 3, Powdered Pigments.

- 4, White Fine Mils Cement.

- 5, Chopped Fibers 3/4″ to 1 1/2″ Long Stranded Prefered.

- 6, Fiberglass Rebar.

- 7, Release Agents.

- 8, Texturing Products Like Baking Soda.

Moving Forward.

Next, I will go through the production area requirements, I hope you have found this an interesting and detailed breakdown of how and what you need. And don’t forget a nice custom contract with an upfront deposit, that can get you started.

Contact Us

We hope you find the information useful, but if you have any questions or need help, send us a message. You do have to sign in and confirm these days to comply with government rules. Sorry for the inconvenience.

Author Rob

Leave a Reply