How To Make Stone Fireplaces, Mantels & Surrounds The Focal Point Of The Room

Background information.

How to make stone fireplaces, mantels & surrounds the focal point of the room they adorn no matter what country it is. Most differences relate to their overall size, the firebox size and fuel type.

Throughout the ages, artisans have produced fireplaces with hearths, mantel supports, mantels, and various surrounds using many different products and a multitude of designs.

I/We promote transparency. This post or site may contain affiliate links. This means only if you make a purchase through these links, not just by clicking, I/we may earn a small commission at no extra cost to you.

As an Amazon Associate, I earn from qualifying purchases

Resurgence of Fireplaces

Today, the spiralling cost of fossil fuels used for heating systems drives the resurgence of modern fireplaces in the UK and the USA. Many of these are in the form of a log burner which can be a compact and efficient source of heat.

But these are not as homely as an open fire with the crackle of logs burning. Sadly, they are just not as efficient as the smallish multifuel burners.Others often place many of these in the same area as the old fireplace, using a custom-made fireplace mantel.

Most countries have many regulations for the building of fireplaces and parts of the surrounds to the firebox. The primary reason for this is safety, the saving of lives and the destruction of property. In today’s world, even technology plays its part with fire and CO2 detector systems, remote controlled fireplaces that can even be operated from your phone.

How To Make Stone Fireplaces, Mantels & Surrounds With Cast Stone.

Architectural cast stone is a great choice for today’s fireplaces, mantels and upper or lower surrounds. It’s non-combustible and there is an inexhaustible and flexible choice for designs.

In many areas of the States like North Carolina, especially in country or golf club settings, I have seen monstrous natural stone fireplaces 25’-30’ tall. But these stone fireplaces and hearths were not real stone. They were cast stone products, like Eldorado or Cultured Stone veneers, which convincingly imitate natural rocks.

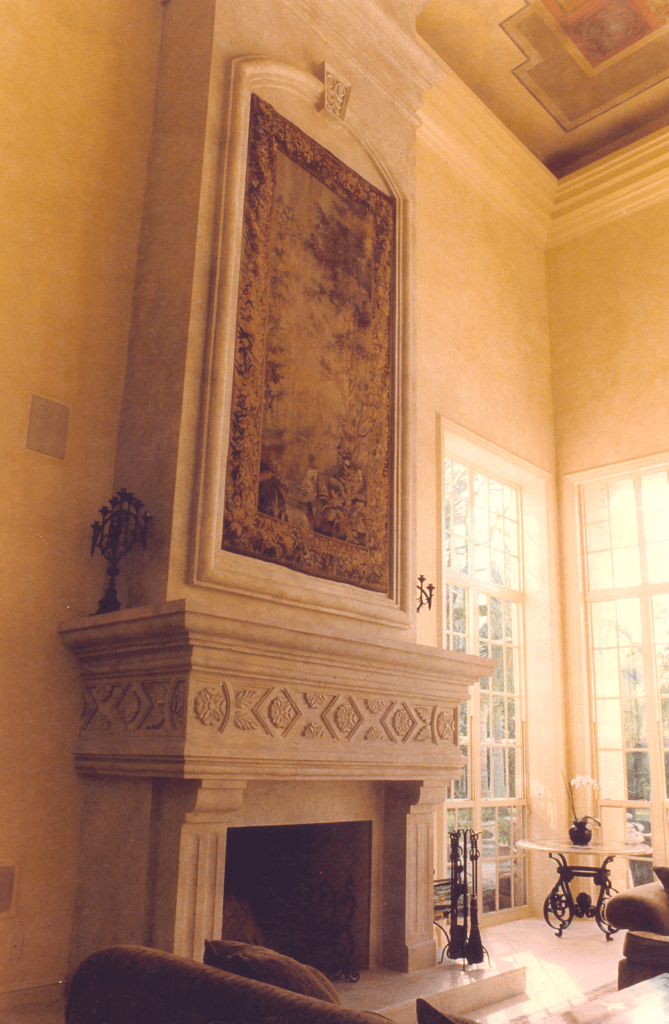

I worked heavily with my company from the early 90s to 2011 in fabricating and installing many fireplaces. Clients called us in to either suggest designs or collaborate with an interior decorator to achieve the desired result. And some have been absolutely huge fireplaces, some 10m (30’) tall, and even the same in width, although these did include other usable elements in the design.

Choosing The Elements For The Stone Fireplaces, Mantels & Surrounds.

Clients, decorators, or builders always involved us at an early stage so we could advise them on the best way to achieve the design or inform them of any additional buildout/structure required to achieve the client’s vision. A good starting point was always to ask the client if they had seen anything in a magazine, or if they had a photo of anything that had caught their eye. We used to show our portfolio of past projects or new major elements we now could provide.

It was always important to get a feel for the client’s tastes and preferences early in the process. At this first meeting, and if it wasn’t already in place, a choice of the firebox was made. Its position off the floor and its position on the wall where it was being built was finalised. Most of these boxes were of metal designs and used gas, artificial logs and embers, very effective for looks and no mess. Others could be of a fire brick construction and could be used for solid fuels.

Fireplace. Gas & Electric Considerations.

Addressing all these points was important for installing the gas supply or any electrical requirements and for drawing up the designs. We took all field measurements if the structure or walls were already built. At the same time, we noted the type and position of the firebox, and any obstacles or other potential issues. Some questions were always raised about basic design parameters. What would you prefer the height of your mantel to be? What is your preference for your mantel support, column(s) or corbels? How much display space would you like on top of your cast stone mantel? do you have any artwork, mirror or tv that needs to fit in the upper stone fireplace & mantel surround?

The last part of the puzzle for the first meeting involved deciding on the type, texture, and color of the cast stone. This task was always easier with an interior decorator’s involvement. Typically, the choice of cast stone came down to two options: limestone or coral stone. Limestone always has a smooth texture, while coral stone comes in three distinct textures: heavy random, medium, and light. When it came to colour, we always offered 5 standard colours or the choice of a custom colour at additional cost. Anyone considering enquiring with a cast stone company about a fireplace should have the following readily available.

Fireplace And Surround Check List.

- Have your ideas ready, photos, and magazines.

- Any fire box picked out.

- The type of cast stone you would like.

- The colour and finish of your cast stone.

- Your preferred height of the top of your mantel

- How much display space on your mantel is needed?

- What style of mantel support is preferred?

- Information on any item you want incorporated.

Production Of The Fireplace Mantel.

Over time I developed a system that was based on ease of installation. And to eliminate much of the additional costs associated with complex buildouts/structures required for these behemoths or even the smaller designs. We came across this situation about 80% of the time. And it had led to many more mistakes, and even worse potential for an unsatisfactory installation of the cast stone. As we could be at any given time working on as many as 5 of these projects in a territory stretching from Key West to the Hamptons in New York State. My goal was to Mmake things easier all around and cut out potential mistakes throughout the process.

So with all field measurements to hand, the client’s design and choices met, signed off paperwork for all elements, and the process of producing the cast stone fireplace, mantel & surrounds began. It was always wise at this point to check with the builder or designer, one last time, that there had been no changes. Even if we did have all the sign-offs.

Starting The Production Process.

First, we created individual shop drawings for each assembly part. Simultaneously, our custom-built software generated thermal tags for the number of pieces, job ID, and location, complete with barcodes for tracking. After attaching the tags, we sent them to our mold shop to check for mold availability

Making The Design Work.

We designed each piece to fit together in the field, requiring many calculations at the shop drawing stage to enable this. Allowances for grout joints and any returns were 2 of the many considerations. But the overall design was that the installers had no cuts to make and they could stack the install like a “Lego” kit.

Once the mould shop work was done, the mould(s) would be sent to production. After production each piece went through quality control, dry setting the pieces of the assembly to check for tolerances. And then onto packing and palletising, and storage ready for the future delivery.

Fireplace Installation.

As the scheduled installation date got close, our design office would prepare an installation package. Drawings of the overall fireplace with parts locations noted. Also a list of which pallets they were on. All the details for the colour, address and contact information. We arranged transport, and the installers and we converged on the project simultaneously. They had all the information, setting and grouting materials, and all tools and equipment.

Because I was previously a mason and cast stone installer the implementation of my “Lego” design method, made installation simple and fast. And my installers were very keen to work with my cast stone fireplace mantels and upper surrounds. And most importantly, the contractor and the client expressed extreme satisfaction with the overall finished item

In later articles, I will go into a more detailed description of the various processes mentioned above.

Contact Us

We hope you find the information useful, but if you have any questions or need help, send us a message. You do have to sign in and confirm these days to comply with government rules. Sorry for the inconvenience.

Good afternoon, I really liked the stone material, a fireplace is more delicate and with an air of richness. The camps made of stone are more beautiful and resemble the architecture of royalty, something imposing, tasteful. I believe it is a material that great architects will want to compose their projects. I liked it a lot.

What would be the price list?