Using the processes of 3D Printing For Custom Silicone Molds

Processes of 3D Printing: Revolutionizing Custom Silicone Molds

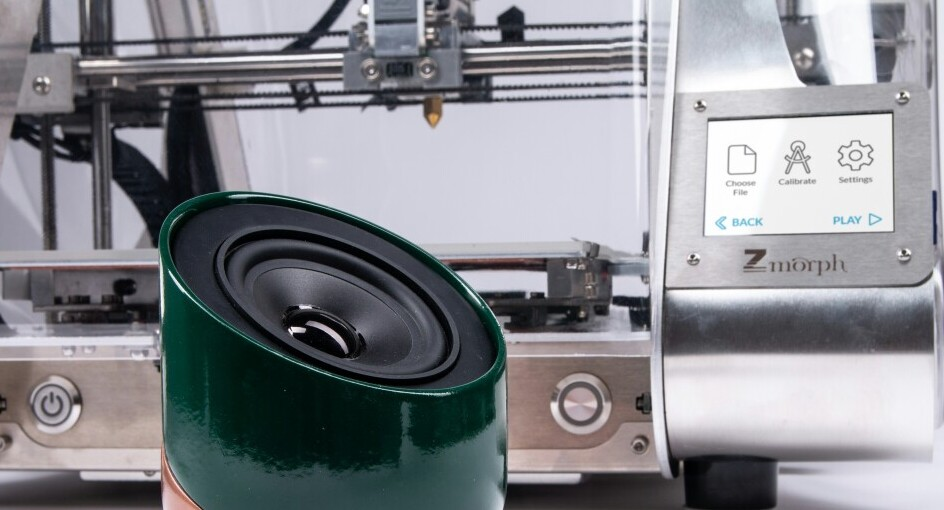

Processes of 3D printing has revolutionized mold-making, offering speed, precision, and flexibility. However, while 3D printing for silicone molds can create molds directly, it’s most effective as a tool for producing models or prototypes that are then finished and then into final molds. This distinction is crucial because 3D printers have limitations, such as print area size and surface finish quality, which can affect the way they are used for large-scale or high quality finished mold for production.

The cost-effectiveness is another area where 3D printing shines. Reduced waste contributes to lower overall costs, Plus, once the form is created, it can be reused multiple times, further stretching its value.

Today’s technology makes this all more accessible than ever. User-friendly printers, like those from Creality, offer affordable ways to jump into 3D printing and they have so many upgrades as your budget permits. Even more advanced models, like Prusa, offer fantastic print quality right out of the box. With so many options, both beginners and professionals can explore this space and discover benefits that were once reserved for large-scale industrial settings.

Understanding the Role of 3D Printing in Mold-Making

Prototyping and Model Creation

Primary Role: The most common use of 3D printers in model-making is to create highly detailed models or prototypes. These prototypes are then used to craft final molds using traditional methods like silicone casting or vacuum forming.

Advantages: 3D printing allows for rapid prototyping, making it easier to iterate designs before committing to final molds. This process is invaluable for testing and refining complex or intricate designs.

Direct Mold-Making Limitations

Print Size Constraints: Most consumer and even prosumer-grade 3D printers are limited by their build area, making it challenging to print large molds in one piece.

Surface Finish: The layer lines from 3D printing often require extensive post-processing to achieve the smooth surface necessary for silicone casting. While sanding or resin coating can help, achieving a perfect finish can still be labor-intensive.

Material Considerations: 3D printed molds may lack the durability required for repeated use or exposure to high temperatures during silicone curing.

By understanding these limitations early, it’s clear that 3D printers excel as tools for creating masters or prototypes, which can then be finished and used to craft molds with higher precision and finished surface quality.

Advantages of Using 3D Printing for Prototyping in Mold-Making

1. 3D Printing for Custom Molds:

Prototyping with 3D printers allows for far greater intricate designs that can be easily modified and this is done in-house. The flexibility of CAD or 3D software ensures that models can be adjusted before creating the final mold from the printed model.

2. 3D Printing Silicone Molds Models with Speed:

Rapid prototyping with 3D printing significantly reduces the time from concept to model, making it easier to refine designs quickly.

3. Cost-Effectiveness:

Prototypes can be printed at a fraction of the cost of traditional master-making methods, especially for one-off designs or experimental pieces and right there in your work area.

4. Scalability:

Models created with 3D printers can serve as a base for molds to be made in a variety of materials, from silicone to plaster or resins, depending on the final application.

Applications of 3D Printing in Mold-Making

Prototypes for Final Mold Creation

3D printing is ideal for producing prototypes that can be further finished and used to craft molds through traditional processes. For example:

A 3D-printed model can be sanded, polished, or coated with resin or a simple spray paint to achieve the desired finish before creating a silicone mold.

Large molds can be crafted by printing smaller components that are assembled into a complete master.

Small-Scale Molds

While 3D printers are not optimal for large-scale molds, they can produce smaller molds for items like jewelry, resin castings, or intricate craft pieces.

Case Studies and Examples

Jewelry Prototypes

Designers use 3D printing to create intricate prototypes for rings, earrings, and pendants. Then polish the prototypes to create high-quality silicone molds for casting metals and resins

Craft Projects

Hobbyists utilize 3D printers for small resin or plaster molds, creating unique decorative items or personalized gifts. Flexible filaments and detailed designs enable intricate customizations.

Comparisons Between 3D Printing and Traditional Methods

1. Custom Silicone Mold Technology and Precision:

Traditional methods like CNC milling offer unmatched precision for industrial-scale projects, but they’re costly and require specialized equipment.

3D printing excels in rapid prototyping and small-scale projects but may lack industrial-grade precision without post-processing.

2. Flexibility:

Hand-carved models are time-consuming and require advanced skills.

3D printing offers repeatability and easy modifications, even for beginners

Materials Section

Filament Options for Prototyping

1. PLA: Affordable and easy to use, but not suitable for molds requiring durability or heat resistance.

2. ABS: Which is far more durable and it can be smoothed with acetone, but it does require great ventilation due to fumes.

3. PETG: Heat-resistant and durable, making it ideal for more demanding applications.

4. Specialty Resins: SLA printers can produce prototypes with smooth finishes, reducing the need for post-processing.

Post-Processing Techniques

1. Sanding and Polishing:

Use fine-grit sandpaper to smooth layer lines on 3D prints.

Wet sanding can achieve a polished finish for better silicone casting results.

2. Resin Coatings:

Apply epoxy or resin to enhance surface quality and durability.

This step ensures the final mold reflects the smoothness of the prototype.

3. Assembly of Multi-Part Prototypes:

By combining smaller parts of printed sections it is then possible to form the larger molds. Proper alignment and adhesive selection are crucial.

Safety Considerations

1. Printer Safety:

Ensure proper ventilation when printing with ABS or other filaments that release fumes.

Avoid touching heated elements of the printer.

2. Material Handling:

Use gloves and masks when working with silicones, resins, or solvents.

Store materials properly to prevent contamination or degradation.

Future Trends in 3D Printing for Mold-Making

1. Emerging Materials:

Flexible filaments and high-temperature plastics are expanding the range of applications for 3D printed prototypes.

2. AI-Assisted Design:

CAD software integrated with AI can optimize designs for better mold performance.

3. Larger Build Areas:

Innovations in large-format 3D printers may overcome current size limitations, enabling the direct printing of larger molds.

FAQs: Common Questions About 3D Printing for Molds

1. Can I directly 3D print a silicone mold?

While it is possible, to direct 3D printing of a mold to pour a silicone piece, often it requires significant post-processing to ensure smooth surfaces and durability because silicone reflects the exact surface you give it. It is easier to print your model and be in control of the finish snd so the future mold.

2. What’s the best filament for making prototypes?

PLA for affordability, PETG for durability, and ABS for heat resistance are popular choices. PLA is the most common and more readily available.

3. How do I scale up a mold with a small printer?

Print the design in sections that suit the design of what you are making and assemble them using adhesives or mechanical connectors.Prusa printers offer this option, mesh mixer by auto desk has a free feature and an option o use “Plane Cut”. Ultimaker Cura is another one, Tinker Cad and Simplify 3D. I am sure there are others.

Conclusion: Unlocking the Potential of 3D Printing in Mold-Making

While 3D printing for silicone molds is an exciting development, its true strength lies in creating prototypes and models that serve as the foundation for high-quality mold production. Recognizing the limitations of print size and surface finish allows makers to leverage the technology effectively and combine it with traditional techniques for the best results.

If you’re ready to explore this world of fascinating possibilities, consider starting with Creality for affordability and lots of upgradability as your budget permits or Prusa for professional-grade precision. Whichever you choose, 3D printing offers an incredible opportunity to innovate and refine your mold-making process in such an interesting way, I remember the hype and intrigue when the first color lase printer came out, so slow!

3D printing has brought a revolutionary twist to mold-making, offering unparalleled speed, precision, and flexibility that were once hard to achieve. In the past, creating molds for silicone casting often required intricate craftsmanship and long lead times. Now, with 3D printing, what used to take weeks can happen in days—even hours.

One of the biggest perks of using 3D printing for custom molds is efficiency. It allows for rapid prototyping, making it easier to iterate designs until the result is spot-on. The ability to scale each project based on specific needs provides a level of control that’s a game-changer for designers and makers alike.

Processes of 3D Printing & Toolmaking.

3D printing is particularly beneficial because it democratizes toolmaking. Even if you’re just starting out, you can dive into mold-making thanks to the accessibility of 3D printers and software tools. It opens up a world of possibilities for customization, letting people bring unique, intricate designs to life with just a few clicks and some know-how.

In my experience as a mold-maker who is adopting to 3D printing, means I’ve seen firsthand how it streamlines workflow which then enhances the creatation process. This technology fits in well with today’s demands for fast production without loosing or compromising on quality. Whether working on a professional project or it is just part of a hobby, the simplicity provided by using 3D printing is nothing short of incredible.

Contact Us

We hope you find the information useful, but if you have any questions or need help, send us a message. You do have to sign in and confirm these days to comply with government rules. Sorry for the inconvenience.

Author Rob

An excellent overview of how 3D printing is transforming mold-making! The article does a great job of highlighting the strengths and limitations of 3D printing for custom silicone molds, particularly the focus on using 3D printers for prototyping rather than direct mold creation. The balance between accessibility for beginners and the precision needed for professionals is well-explained.

The practical advice on post-processing and material choices is especially helpful, as these are crucial for achieving high-quality results. It’s exciting to see how this technology is democratizing mold-making and opening doors for innovation across various industries. Future advancements like AI-assisted design and larger build areas will undoubtedly push the boundaries even further. Great read for anyone interested in this fascinating intersection of technology and craftsmanship!

Hi Loshane,

Thank you for your comments and I am glad you found the article informative, I hope you get the opportunity to put some of it into action.

Rob

This article does a fantastic job of showcasing how 3D printing has transformed the mold-making industry, making it more accessible, efficient, and precise. The explanation of how 3D printers are best utilized for prototyping and model creation highlights their versatility while acknowledging their limitations in direct mold production. The insights into different filament options, post-processing techniques, and printer recommendations, such as Creality and Prusa, make the article practical and valuable for both beginners and professionals.

The section on the advantages of 3D printing, like rapid prototyping and cost-effectiveness, truly captures its game-changing potential. I also appreciate how the article explores future trends, like larger build areas and AI-assisted design, which spark excitement for what’s next in this evolving field. This guide not only informs but inspires makers to innovate and refine their processes, opening up new creative possibilities in custom silicone mold-making.

Hi Laura,

I am happy to hear you found the article interesting and that it has hopefully given you some pointers for a time when you move into this arena.

I think 3-D printers will be like coffee machines and microwaves in households very soon.

Rob