What You Need to Know First Before Manufacturing

Wet Cast Stone Explained.

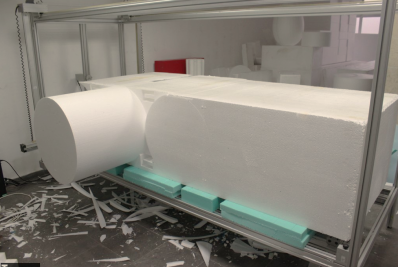

What You Need to Know First Before Manufacturing. Lets start by clarifying what wet-cast architectural precast stone is. Simply put, it’s a type of precast product that mimics the look of natural stone and made with a wet mix rather than the more common dry tamped precast. You’re going to find out about how this is a versatile material extensively used in building facades, garden ornaments, and architectural trims. The wet-cast production process allows for intricate designs and details, making it a favourite among architects and designers.

I/We promote transparency This post or site may contain affiliate links. Which means only if you make a purchase through these links, not just by clicking, I/we may earn a small commission at no extra cost to you.

As an Amazon Associate, I earn from qualifying purchases

Essential Information Before Starting Manufacturing

What you need to know first before manufacturing will include an overview of the ins and outs of the wet-cast process and the different considerations. Now, this isn’t just about pouring concrete into a mold; it’s a fine-tuned operation that blends art with science. From the choice of aggregates to the control of the cement & colour content, every step is crucial. In my opinion, it’s the attention to detail that elevates the quality of the finished natural-looking product.

You’re probably wondering how this technique fits into modern architecture. It’s all about customization and flexibility. Architects can shape wet-cast stone into nearly any form that a mould can create, enabling the construction of structures that might be unfeasible with quarried and hand-carved stone. This includes ornate historical restorations as well as sleek, contemporary designs. Don’t worry too much about constraints, because with wet-cast stone, there are very few when it comes to design. Unlike the alternate method of dry tamped cast stone which we will explain in another article.

Speaking of designs, the next section is especially exciting. You can always adjust your approach down the route of design. But knowing about the vast array of colours and textures available will expand your horizon from the get-go. Choose something that works for you and the overall concept of your project. Now let’s explore the aesthetic versatility of wet-cast stone finishes that breathe life into architecture.

Foundational Tips Before Manufacturing of Wet-Cast Stone Finishes

This isn’t just about functionality, what you need to know first before manufacturing is also about the beauty that wet-cast stone brings to a building’s facade or interior space. The production process is intricately designed to not only ensure the structural integrity of the individual stone pieces but also to bring an architect’s vision to life through a myriad of possible finishes.

You’re going to find out about the rich variety of finishes that can be achieved with wet-cast methods. From the rugged, weathered look of an ancient castle to the smooth, refined finish of a modern museum, or even a textured finish that mimics the look of natural coral stone, the possibilities are nearly endless. Aesthetic customization is one of the greatest strengths of wet-cast stone, providing designers the freedom to create details that truly complement their architectural conceptual designs.

Important Facts to Understand Before Manufacturing About Color and Texture

Colours play a pivotal role in the versatility of wet-cast stone. By incorporating different pigments into the mix, and in many cases this can be several different pigments to create a perfect natural stone colour and using white cement in many mixes, manufacturers can produce cast stone in virtually any colour. Imagine a spectrum ranging from earthy, natural tones to vibrant, contemporary hues. With a skilled production worker and 2 or 3 different mixes, a dramatic marbling effect can be achieved. These capabilities allow wet-cast stone to either blend seamlessly with traditional environments or stand out as a statement piece in modern settings.

Then there’s texture, the touch-and-feel aspect of cast stone that can change the character of a space. To create textures and surfaces that replicate natural stone finishes such as limestone, granite, or travertine, use techniques like acid etching, sandblasting, or other treatments in the moulds prior to casting, or apply complex post-casting tooling and finishing

This mimetic ability allows wet-cast stone to replicate traditional stone finishes and create unique textural effects that play with light and shadow, adding depth and richness to architectural elements I will dive deeper into many of these finishing and casting techniques in future posts.

Strength and Endurance: Reinforcing Cast Stone Elements

So after discussing the aesthetic aspects, let’s turn our attention towards the integrity of wet-cast stone. I’m going to help you understand the reinforcing requirements that make this material not just beautiful but also durable. ow, reinforcing cast stone is not always crucial, but it is necessary for some elements, especially in architectural projects exposed to extreme weather events or where safety issues are paramount.

When it comes to reinforcing. Most people typically think we are talking about adding steel materials into the molds before casting to enhance strength. With wet-cast stone this isn’t really about making the stone structurally tougher. It’s more about ensuring it can withstand the stresses and strains of transportation and its final environment. One common misconception is that using steel bars or mesh, which is known technically as rebar. But rebar is not the product for this job.

Key Insights Before Beginning Manufacturing

What we had used for many years and that I still would recommend today in any decorative architectural cast stone pieces. Except in rare occasions where the need for structural performance is critical. I learned the hard way and I only used non-ferrous reinforcing. It is important to understand that in most circumstances the thickness of cast stone is a fraction of structural cast stone. Therefore it is virtually impossible to attain conventional coverages needed for the use of the ferrous rebars.

What You Need to Know First Before Manufacturing And Reinforcing

There’s more than just steel available. I’ve seen some pretty interesting developments, over the years with the use of fibreglass rebar in many sizes, and with fibres of many types and lengths that you can add to your mixes and composite materials like carbon fibre entwined with other types of fibres, which are gaining popularity for their strength-to-weight ratio and corrosion resistance. Designers have specifically created some types for use where bomb proofing is a requirement. Often, project teams select these newer types of reinforcing based on specific needs, such as the climate and engineering design goal

You might wonder about the techniques for placing these reinforcements or how they affect the wet-casting process. Don’t worry about this; remember that engineers can calculate the type and amount of reinforcing if needed. They will take into account factors and any extenuating circumstances. Remember architectural precast stone is not a structural element in 99% of cases, so the rigours of structural cast stone panels, or structural concrete to not apply here.

In conclusion, the right reinforcing for your cast stone project may depend on many factors. But you would not normally participate in that decision process. However, being informed early on, with both aesthetics and structure in mind, is beneficial. This may help you with your decisions and avoid costly overruns. And, if you want to know more or need assistance. I’m here to help you navigate through the choices to find the best solution for your architectural vision.

Contact Us

We hope you find the information useful, but if you have any questions or need help, send us a message. You do have to sign in and confirm these days to comply with government rules. Sorry for the inconvenience.

Author Rob

Leave a Reply